Joint Development of an Engineless, Full Battery Rigid Dump Truck with ABB

24th June, 2021

Realizing a low cost, maximum load capacity and high operation rate by the dynamic charging system with trolley

Tokyo, 23 June 2021 —Hitachi Construction Machinery (TSE: 6305; “Hitachi Construction Machinery”) and ABB today announce that they have signed a collaboration agreement to develop an engineless, full battery rigid frame dump truck (hereinafter, “full battery dump truck”) with a customized on-board energy storage system, reducing greenhouse gas emissions and offering a solution towards a net zero emission pathway.

Hitachi Construction Machinery Group’s parts remanufacturing business involves collecting, disassembling and repairing customers’ used genuine parts, such as hydraulic cylinders, hydraulic pumps and travel device, and then providing for reuse as remanufactured parts with the same function warranty as new parts. Parts remanufacturing business in the Southeast Asian region has been remanufacturing used parts and supplying to Indonesia, mainly for mining products, but transportation costs and turnaround were a problem due to the need to route the supply of remanufactured parts for medium to large-sized hydraulic excavator to countries and regions other than Indonesia via Japan.

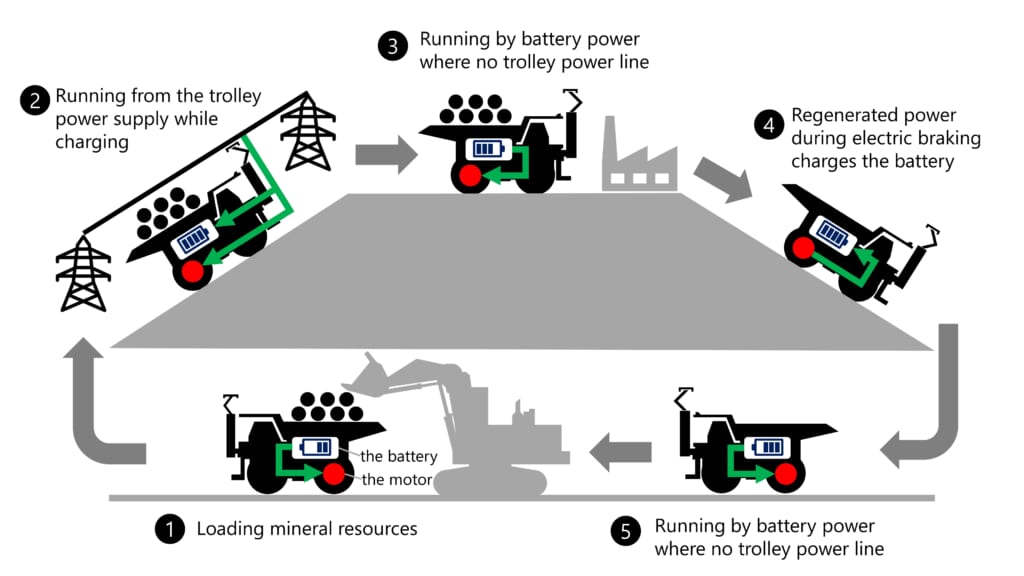

Utilizing ABB’s innovative battery technology, Hitachi Construction Machinery trucks can be transformed from diesel to full electric battery operation. The dump trucks will operate by utilizing a new onboard electrification system – drawing its energy requirements from an energy supply system with dynamic charging, allowing simultaneous charging of the on-board energy storage system while providing energy to power the truck. The system will provide extended battery longevity by reducing the load and discharge during each haul cycle, offering a cost efficient industry solution that allows continuous operation so as to maintain the high productivity and performance the industry has come to expect from Hitachi Construction Machinery products.

Both companies signed a memorandum of understanding in March 2021 to build a partnership aimed at realizing net zero emissions and this joint development is the first project where the two companies will apply their complementary skills to achieve this goal. ABB will develop the on-board energy storage systems by customizing an existing product and Hitachi Construction Machinery will lead the overall design and development of the dynamic charging battery dump truck utilizing the technology of its existing rigid dump truck with trolley as its base, effectively allowing the accelerated development of this solution.

Hitachi Construction Machinery and ABB understand there is a growing interest in the electrification of mining operations and machinery, as environmental awareness grows within the industry and community. Technology continues to be further developed in an effort to reduce greenhouse gas emissions, while taking into consideration the demands of mining operations.

By utilizing Hitachi Construction Machinery’s dynamic charging battery dump truck systems and ABB’s battery technology, the joint collaboration will not only help tackle the challenge of solving the issues involved in dump truck electrification, but also provide a real world climate change solution.

Features of the dynamic charging battery dump truck being jointly developed

- Controls the initial and lifecycle costs

By drawing the electrical power from the dynamic charging system required during operation will limit the volume of batteries on the trucks, providing a sustainable solution. In addition, the system aims to reduce the lifecycle costs by drawing electrical power from the overhead system while connected, simultaneously charging the battery in an appropriate manner to reduce the load and depth of discharge, maximizing battery life.

- Reduces the vehicle weight and maximizes the load capacity

Limiting the battery volume lessens the weight of the battery solution on the vehicle, maximizing the battery dump truck’s payload capacity.

- Dynamic charging solution to provide a higher rate of operation over static charging

The solution draws electrical power from the dynamic charging system during operation while simultaneously charging the battery, removing the need to stop the vehicle for recharging. Therefore, achieving a higher rate of continuous operation to maintain productivity at site.

Hitachi Construction Machinery and ABB’s joint solution will contribute to net zero emissions of greenhouse gases from mining machinery, utilizing ABB’s strengths in mining facility control systems, power grids, and overall mining processes, paired with Hitachi Construction Machinery’s extensive trolley truck delivery record and engineering capability in providing a rigid dump truck platform with power-receiving dynamic charging system.

Comment from Edgar Keller, President of ABB’s Motion Traction Division

“We are honored to collaborate with Hitachi Construction Machinery combining extensive industry expertise and innovative technologies to improve efficiency and accelerate the transition to all-electric mine operations. By co-creating solutions, we can help mine operators achieve their production and sustainability goals.”

Comment from Sonosuke Ishii, Senior Vice President and Executive Officer, President of Mining Group

ABB highly values our superiority with respect to electric ultra-large hydraulic excavators, AC drive dump trucks, and diesel engine rigid dump trucks with trolley. The strengths and knowledge of both companies will be utilized to realize the early development of dynamic charging battery dump trucks. In addition, ABB’s energy storage solutions can also be used for static charging dump trucks and the technology is ready for future fuel cell electric vehicles, the basic technologies required for net-zero emissions from mining machinery can also be established as part of the current development. Both companies will continue with the development while looking ahead to the future.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

Hitachi, Construction Machinery Co., Ltd., (TSE: 6305), headquartered in Tokyo, Japan, is a global Construction Machinery company with approximately 25,000 employees worldwide. Fiscal 2020 (ended March 31, 2021) consolidated revenues totaled 813 billion yen. Hitachi Construction Machinery will focus more than ever on the Construction and Mining Machinery Business, which includes Hydraulic Excavators, Wheel Loaders, Rigid Dump Trucks, Compaction Equipment, Applications and Mine Management Systems. For more information on Hitachi Construction Machinery, please visit the company’s website at https://www.hitachicm.com/global/

Top of This Page

Top of This Page